Snake-Arm Robots – They reach the unreachable

U0205081 Chow Synn Nee

U0205081 Chow Synn NeeHaving read an earlier blog entry posted by Shaohua about the Snake-Like Robot – KOHGA, it sparked off my interest about such robots because having a snake-like structure is bound to have many advantages such as easy mobility into awkward spaces and flexibility of motion, which is clearly favourable to applications in maintenance and repair. True enough, as I searched through the Internet for more similar designed robots, I came upon this snake-arm robot, which is designed by OCRobotics Ltd. The functions that the snake-arm robots are designed to fulfill include: precise positioning to place and remove fixtures and sections of pipe, tack welding and inspection.

There are two types of snake-arm robots: the Overhead Arm and the Underneath Arm and the name indicates the direction of access to the working area. These robots are already gaining recognition for their immense applications in the industry and OCRobotics has even won a significant contract to supply these two types of snake-arm robots to a Swedish nuclear power utility for maintenance of their nuclear reactor.

So how exactly does a nuclear reactor look like? Can’t normal robots perform the job as efficiently? Here is a picture showing a nuclear reactor. It’s not difficult now to understand why a snake-arm robot is needed isn’t it? The snake-arm robots gain access to extremely confined area of the nuclear reactor in order to conduct maintenance tasks. On top of this, when the path to the work site is tortuous, dangerous or unpredictable, the flexible delivery mechanism of the snake-arm robot would be able to manoeuvre around the obstacles. The arms are flexible, continuously curved and have multi degrees of freedom. What truly amazes me is that they even boast low cost disposable or ‘sacrificial’ arms of which would, as the name suggests, be sacrificed should it actually find difficulty retracting itself from the work site.

The Technology

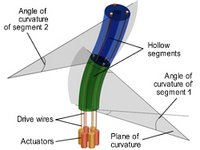

Snake-arm robots are slender and have continuous variable bend along their length. It is, in fact, a little like the human spine, as it is comprised of a large number of “vertebrae”. It is a “tendon-driven” arm with wires terminating at various points along the length of the arm. The result is that the curvature and plane of curvature of each segment can be independently controlled. The robots use what is called wire drive and they have no motors in the arm itself, which leads to a compact low mass design. A control software will then calculate the necessary lengths of all the wires to produce the desired shape.

The operator uses a joystick to drive the tip and the computer does the math to make the arm follow. This tip-following capability enables a snake-arm robot to avoid obstacles and follow its tip into complex structures. The operator can also control the arm in tool or world space, whilst continuing to avoid obstacles. This technology is very scalable and the arms can be designed to be large and durable as well as small and compliant. The snake-arm robots can combine a significant payload with precise positioning and still snake into awkward spaces!

Impressive isn’t it? I guess snake-like structured robots would find more ways to contribute to the industry in the near future because as of now, there have already been similar applications in exploration and industrial/ service robotics to say the least.

Reference:

Official Website of OCRobotics Ltd

http://www.ocrobotics.com/

Picture of nuclear reactor courtesy of Wikipedia.